Technological advances in the midstream sector are reducing emissions while improving efficiency.

Mark Gebbia, VP of Environmental, Regulatory and Permitting, told Hart Energy in a recent article that Williams is seeing big gains by replacing compression units with modern turbines as part of the company’s Emissions Reduction Program (ERP).

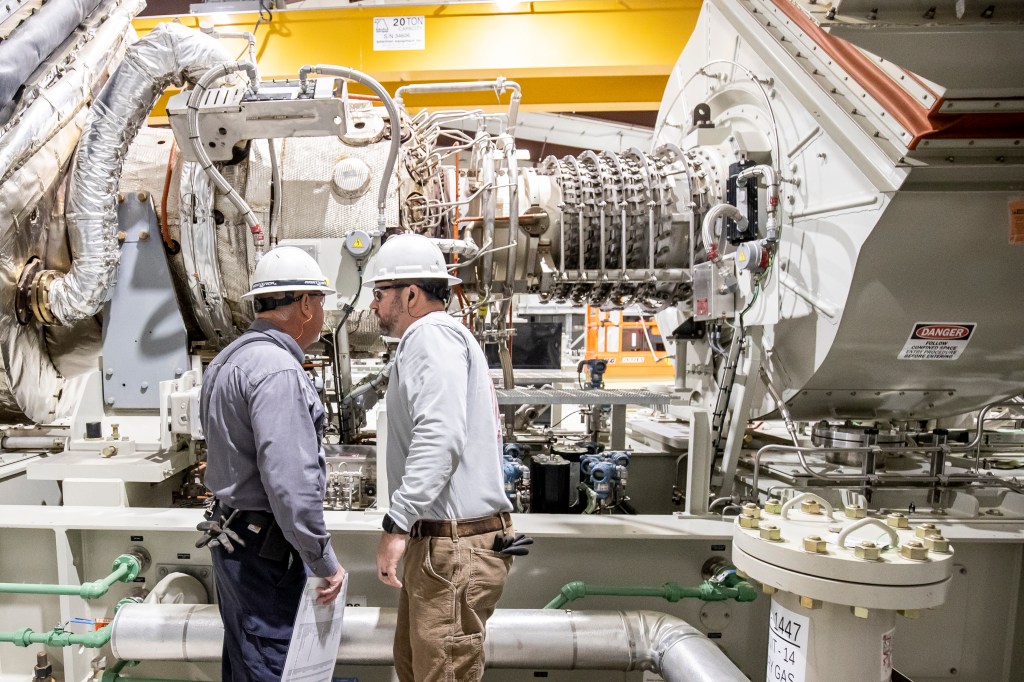

Williams has made substantial progress by switching from higher-emitting reciprocating engines to modern turbines and electric motor drive engines. We also installed seal vent capture systems on these units, further reducing methane emissions.

“We’ve done a lot of work to put the ERP program together,” Gebbia said. “We’ve replaced 112 compression units, and 92 of those were done in 2024.”

One notable example is Station 165 in southern Virginia, part of Williams’ Transco system.

“It was amazing,” he told the publication. “We replaced 10 stand-alone reciprocating engines, with one single block of turbine horsepower. Nitrogen oxide (Nox) emissions were typically reduced by about 98%,” Gebbia said. “And then the methane reductions were pretty significant, too.”

Station 165 before older compressor units removed

Station 165 after older compressor units removed

After removing the older compression units, both the emissions and physical footprints of the facility are greatly reduced. Methane intensity, the amount released per unit of energy created, dropped by 60%.

The ERP initiatives also are expected to reduce equipment downtime and improve reliability for customers.